Le choix des matériaux pour les chaussures de sécurité est vaste. Acier, composite, aluminium, cuir, microfibre, textile, caoutchouc, polyuréthane et EVA figurent parmi les plus courants. Chaque matériau possède des propriétés uniques : certains privilégient la protection, d’autres le confort ou la durabilité.

Choose safety shoes based on your work environment. Consider hazards like falling objects or slippery surfaces to select the right materials.

Understand the benefits of different toe cap materials. Steel offers maximum protection, while composite is lightweight and comfortable.

Prioritize comfort with breathable uppers and supportive insoles. Materials like microfiber and memory foam enhance comfort during long hours on your feet.

When you choose safety shoes, you need to understand how each part uses different materials to deliver protection, comfort, and durability. The following breakdown helps you compare the most common safety shoe materials by component, so you can select the best option for your needs.

The protective toe cap is the heart of safety shoes. It shields your toes from impact and compression hazards. You will find three primary materials used for toe caps:

|

Toe Cap Type |

Weight Difference |

Comfort Level |

|---|---|---|

|

Steel |

Heaviest |

Less comfortable for long wear |

|

Aluminum |

Up to 30% lighter |

More comfortable |

|

Composite |

Up to 50% lighter |

Most comfortable |

Steel toe caps set the standard for protection in work boots. They are tough and reliable, but they add weight and can feel less comfortable during long shifts.

Aluminum toe caps offer similar protection but weigh less, making them easier to wear for extended periods.

Composite safety shoes use toe caps made from carbon fiber, plastic, or Kevlar. These materials are much lighter than steel and aluminum. They do not conduct heat or cold, so your feet stay comfortable in extreme temperatures. Composite safety shoes also work well if you pass through metal detectors often.

ASTM F2413 and F2412 standards require all toe cap materials to meet the same impact and compression tests. You get equivalent protection whether you choose steel, aluminum, or composite.

The upper covers your foot and determines the shoe's durability, breathability, and appearance. You will see traditional leathers, advanced synthetics, and textiles used in modern safety shoes.

|

Material |

Tensile Strength (N/mm²) |

Breathability |

Moisture Management |

Notes |

|---|---|---|---|---|

|

Leather |

≥ 15.0 |

Low |

Moderate |

Tough, abrasion-resistant, classic look |

|

Microfiber |

≥ 135 |

High |

High |

Lightweight, vegan-friendly, easy clean |

|

Textile |

Flexible |

Very High |

Moderate |

Breathable, lightweight, flexible |

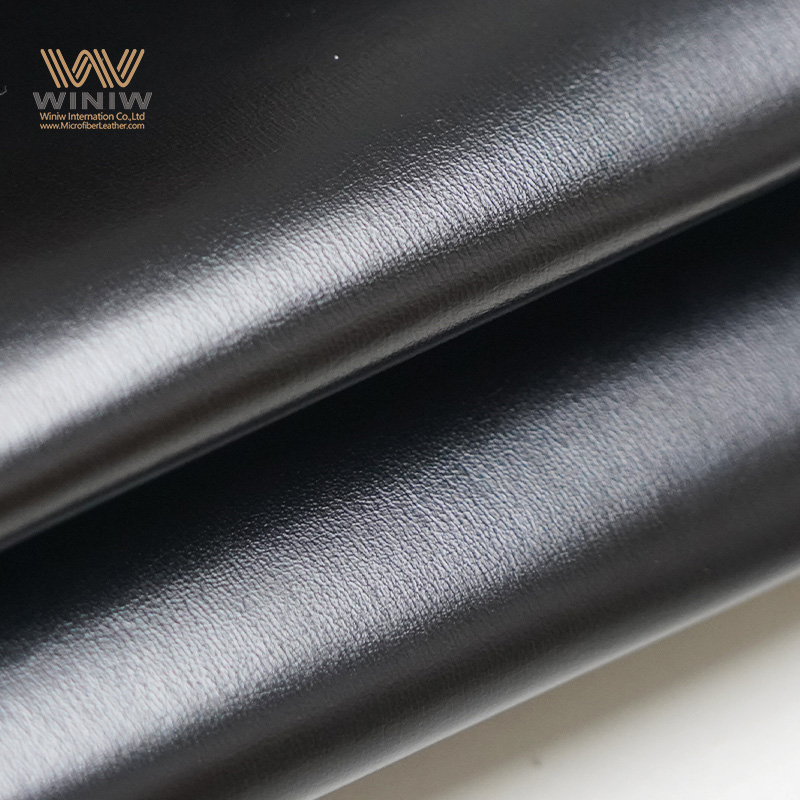

Leather uppers provide high durability and abrasion resistance. They give safety shoes a classic look and feel. You need to maintain leather regularly, but it lasts a long time.

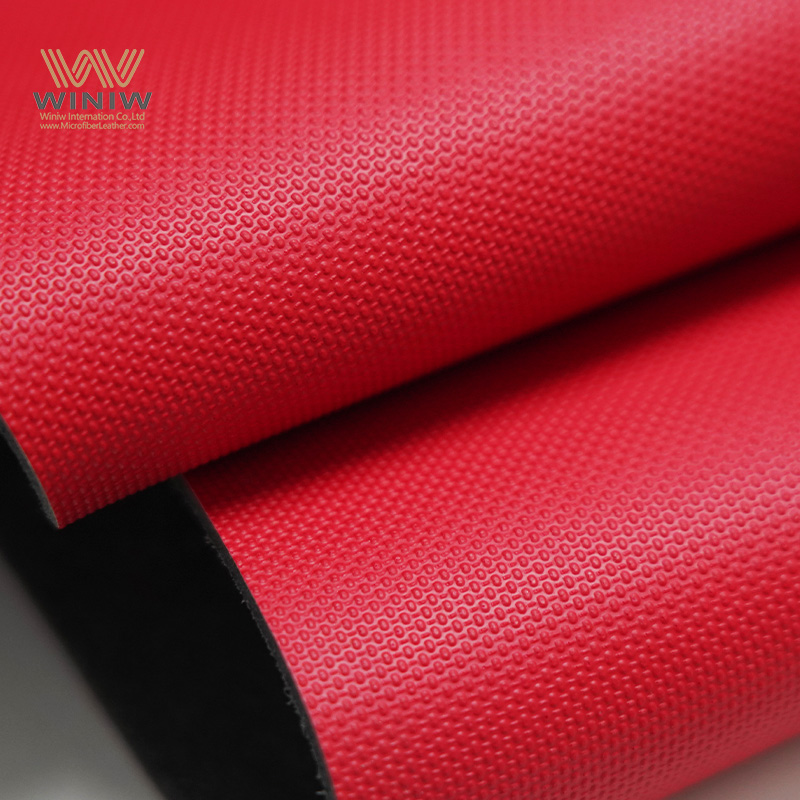

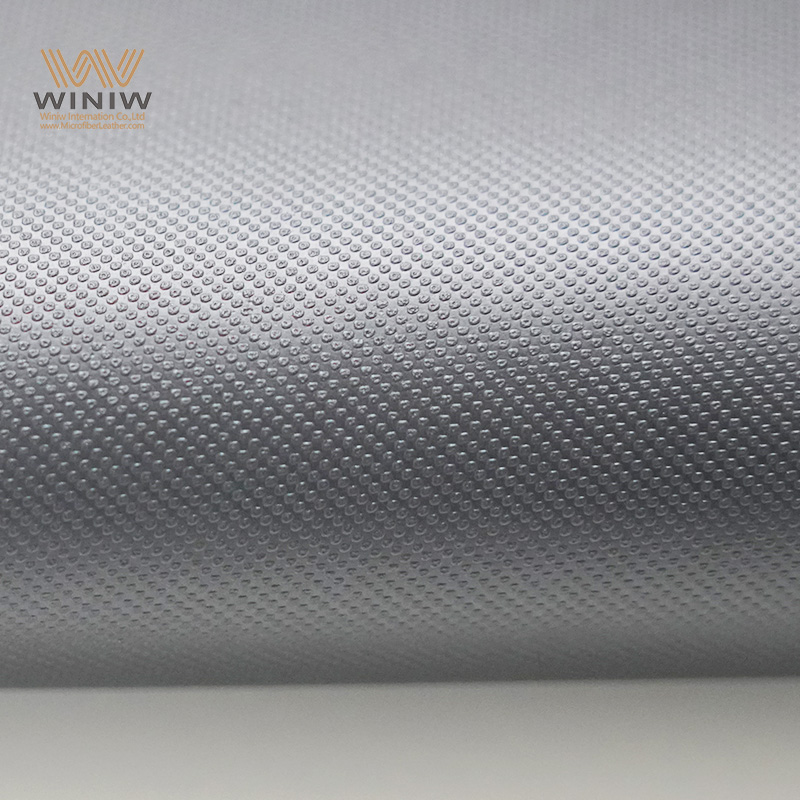

Microfiber uppers stand out for their high tensile strength and resistance to tears. They are soft, flexible, and lightweight. You can clean them easily, and they suit vegan preferences.

Textile uppers offer the best breathability and flexibility. They keep your feet cool and comfortable, especially during long hours. However, they do not match the abrasion resistance of leather or microfiber.

Microfiber and textile uppers in safety shoes material help reduce fatigue and improve comfort, especially in hot environments.

The lining inside safety shoes affects moisture control and overall comfort. You will find mesh and moisture-wicking fabrics as the most common choices.

Mesh linings keep the interior cool and dry. They allow air to circulate, reducing sweat and odor.

Moisture-wicking fabrics draw sweat away from your skin. They help prevent blisters and keep your feet comfortable all day.

Shoes with mesh fabric linings and moisture-wicking materials enhance breathability and comfort, making them ideal for long shifts.

The outsole and midsole protect your feet from slips, chemicals, and fatigue. You need to consider slip resistance, cushioning, and chemical resistance when choosing soles.

|

Component |

Common Materials |

|---|---|

|

Outsoles |

Rubber, Polyurethane (PU), Ethylene Vinyl Acetate (EVA) |

|

Midsoles |

Steel, Flexible Woven Fabrics (Kevlar) |

Rubber outsoles deliver excellent slip resistance and shock absorption. They resist water and chemicals, making them perfect for hazardous environments.

Polyurethane (PU) outsoles are lightweight and durable. They resist oils and chemicals, and they provide good flexibility and shock absorption.

EVA outsoles are the lightest option. They offer great cushioning and flexibility, which helps if you stand or walk for long periods. EVA soles may not last as long as rubber or PU, but they still provide decent slip resistance.

Rubber and PU soles in safety shoes material are best for tough work environments, while EVA suits jobs that require comfort and flexibility.

The insole supports your foot and reduces fatigue. You will find foam, gel, and memory foam as the primary materials.

Memory foam insoles mold to your foot's shape. They distribute pressure evenly and help prevent soreness.

Gel insoles focus on shock absorption. They cushion your steps but do not offer the same personalized support as memory foam.

Foam insoles provide basic comfort and support. Some safety shoes use penetration-resistant insoles made from steel or woven fabrics for extra protection.

A combination of memory foam and arch support in safety shoes materials promotes long-term foot health and comfort.

|

Component |

Common Materials |

|---|---|

|

Toe Caps |

Steel, Aluminum, Composites (Carbon Fiber, Plastic, Kevlar) |

|

Uppers |

Full-grain Leather, Nubuck , Suede, Synthetics, Textiles |

|

Outsoles |

Rubber, Polyurethane (PU), Ethylene Vinyl Acetate (EVA) |

|

Midsoles |

Steel, Flexible Woven Fabrics (Kevlar) |

|

Insoles |

Wool, Leather, Non-woven Fabrics, Foam, Gel, Memory Foam |

Tip: Leather and steel remain the most prevalent safety shoe materials, but advanced synthetics and composite safety shoes are gaining popularity for their comfort and performance.

When you compare safety shoe materials, protection stands out as the top priority. Toe caps made from steel, aluminum, and composite materials all meet strict safety standards like ASTM F2413 and EN ISO 20345. These standards require each material to pass impact and compression tests, so you get reliable protection no matter which option you choose.

|

Material |

Impact Resistance |

Weight |

Corrosion Resistance |

|---|---|---|---|

|

Steel |

Excellent protection against heavy objects |

Heavier than aluminum |

Prone to rust without coating |

|

Aluminum |

Good protection, lighter than steel |

Lighter than steel |

More resistant to corrosion than steel |

|

Composite |

Reliable protection, very lightweight |

Lightest option |

Generally resistant to corrosion |

Steel toe caps offer the highest level of protection and puncture resistance. You can trust them to shield your feet from falling objects and sharp debris.

Aluminum toe caps provide good protection and weigh less, which helps reduce fatigue.

Composite safety shoes use toe caps made from carbon fiber, plastic, or Kevlar. These materials are lightweight and do not conduct electricity, making them ideal for electrical hazard environments.

Steel and composite toe boots both pass electrical hazard safety tests. You can rely on either for insulation against electrical shocks.

Modern safety shoes also feature penetration-resistant insoles. These insoles protect you from sharp objects like nails or glass, adding another layer of safety.

Comfort matters when you spend long hours on your feet. The choice of safety shoes material for uppers, linings, and insoles affects breathability and moisture control.

Leather uppers mold to your feet over time, providing a custom fit. They offer moderate breathability but require regular maintenance.

Microfiber and textile uppers deliver high breathability and flexibility. You feel less fatigue and stay cooler, especially in hot environments.

Mesh linings and moisture-wicking fabrics inside modern safety shoes help keep your feet dry and comfortable. These materials draw sweat away and reduce odor.

Insoles play a key role in comfort. Foam, gel, and memory foam insoles adapt to your foot shape and provide shock absorption capacity. Cooling insoles made from gel and moisture-wicking fabric help regulate temperature and prevent heat buildup.

Memory foam insoles create a custom fit and alleviate pressure points.

Gel insoles offer superior shock absorption and moisture control.

Odor control and moisture-wicking properties keep your feet fresh and dry.

If you want maximum comfort and breathability, choose safety shoes with textile uppers, mesh linings, and memory foam or gel insoles.

Durability determines how long your safety shoes last under tough conditions. The safety shoe materials used for uppers and soles affect lifespan and maintenance needs.

|

Material Type |

Average Lifespan (Heavy Use) |

Average Lifespan (Light Use) |

Maintenance Requirements |

|---|---|---|---|

|

Full-Grain Leather |

6 months |

12 months |

Regular cleaning and maintenance to prevent cracking |

|

Synthetic Blends |

Shorter than leather |

Variable |

Less maintenance, but potentially faster wear |

|

Thin PVC |

Shortest lifespan |

Variable |

Minimal maintenance, but prone to damage |

Leather work boots last longer and resist abrasion, but you need to clean and condition them to prevent cracking.

Synthetic uppers require less maintenance and are easy to clean, but they may wear out faster under heavy use.

Thin PVC offers minimal durability and is prone to damage.

For toe caps, regular cleaning prevents material breakdown. You should inspect for cracks or dents and replace your safety shoes if the toe cap is exposed or the sole wears out. Store your footwear in a dry, cool place to avoid mold and degradation.

Proper maintenance extends the life of your safety shoes and preserves safety footwear performance.

Weight and flexibility influence how comfortable and mobile you feel at work. The materials used for toe caps and soles make a big difference.

|

Property |

EVA |

Rubber/Polyurethane |

|---|---|---|

|

Weight |

Lightweight |

Heavier |

|

Shock Absorption |

Superior |

Moderate |

|

Flexibility |

High |

Moderate to Low |

|

Comfort |

Excellent |

Good |

|

Structural Support |

Lower |

Higher |

|

Breathability |

Low |

Higher |

EVA soles are lightweight and flexible. You get excellent comfort and shock absorption, which helps if you stand or walk for long periods.

Rubber and polyurethane soles provide higher structural support and breathability. They are heavier but offer good slip resistance and durability.

Toe caps also affect weight. Steel is the heaviest, while aluminum and composite safety shoes are much lighter. Composite safety shoes do not trigger metal detectors and resist corrosion, making them a smart choice for jobs that require mobility and flexibility.

If you want maximum slip resistance and flexibility, look for safety shoes with EVA or rubber outsoles and composite toe caps.

Choosing the right safety shoes material depends on your work environment and hazards. You need to match the features of safety shoe materials to your job requirements.

|

Industry |

Key Hazards |

Recommended Features |

|---|---|---|

|

Construction |

Falling objects, sharp materials, electrical hazards |

Reinforced toes, puncture-resistant soles, electrical hazard protection |

|

Manufacturing |

Heavy machinery, moving parts, slippery surfaces |

Slip-resistant soles, metatarsal guards, oil-resistant materials |

|

Healthcare |

Biological hazards, sharp objects, chemical exposure |

Chemical-resistant materials, slip-resistant soles, closed-toe designs |

|

Type of Shoe |

Features |

Recommended Use |

|---|---|---|

|

Electrical Hazard Boots |

Non-conductive, shock-resistant soles, insulation against electrical shocks up to 18000 volts |

Electricians, utility workers |

|

Chemical-resistant Footwear |

Constructed from materials compatible with specific chemicals |

Workers exposed to chemical hazards |

|

Thermal Insulated Shoes |

Insulation against extreme temperatures, waterproofing |

Workers in extreme weather conditions |

For construction, reinforced toe caps and penetration-resistant insoles protect against falling objects and sharp debris. Electrical hazard boots with non-conductive soles keep you safe from shocks.

In manufacturing, slip resistance and oil-resistant outsoles help prevent accidents around heavy machinery and slippery surfaces.

Healthcare workers need chemical-resistant materials and closed-toe designs to guard against biological and chemical hazards.

Always consider the hazards in your workplace before choosing safety shoes. The right safety shoe materials improve protection, comfort, and performance.

You face trade-offs when selecting safety shoes material. Leather uppers offer strong protection and durability, but they cost more and require regular care. Synthetic uppers are lightweight, flexible, and affordable, but they may wear out faster.

|

Feature |

Synthetic Work Boots |

Leather Work Boots |

|---|---|---|

|

Weight |

Lightweight, more flexible |

Heavier, sturdier |

|

Durability |

Moderate, may wear faster |

High, long-lasting |

|

Comfort |

Immediate comfort, less break-in |

Breaks in over time, molds to foot |

|

Protection |

Basic against elements |

Strong protection against water, mud, debris |

|

Maintenance |

Easy wipe-down |

Requires conditioning/cleaning |

|

Price |

Generally more affordable |

Higher upfront cost, long-term value |

Steel toe caps provide maximum protection but add weight. Composite safety shoes are lighter, resist corrosion, and do not conduct electricity. Aluminum toe caps offer a balance between weight and protection.

When you choose safety shoes, balance protection, comfort, and durability. Consider the specific hazards and demands of your job to select the best safety shoes material for your needs.

You improve protection, comfort, and durability by choosing the right safety shoes. Modern safety shoes use advanced soles, penetration-resistant insoles, and ergonomic outsoles to boost performance.

Comfort, fit, and slip resistance reduce fatigue and injury risk.

Always match your footwear to workplace hazards and consult product information or experts for the best choice.

|

Feature |

Impact on Worker Health |

|---|---|

|

Custom insoles |

Reduce pressure, boost comfort |

|

Durable soles |

Prevent foot problems |

Steel gives you maximum protection. Composite offers lightweight comfort and insulation. Aluminum balances protection and weight. Choose based on your work environment.

Use a soft brush to remove dirt.

Wipe with a damp cloth.

Apply leather conditioner for durability.

|

Material |

Durability |

Maintenance |

|---|---|---|

|

Leather |

High |

Regular |

|

Synthetic |

Moderate |

Easy |

Leather lasts longer. Synthetic needs less care but may wear faster.

Analyse de wechat: